blown film machine specification

Although believed to be correct the machine specifications and lists supplied are based solely upon those provided by the original owners. With our unique blown film extrusion know-how of more than five decades we support you to choose the best machine.

Blown Film Plant Three Layer Blown Film Line Non Ibc Ibc

Monolayer 1 Layer Two Die Heads Single Screw.

. Specification Of Monolayer Two Layer Three Layer Extruder Machines. HM LD LDPE Monolayer Two Layer Three Layer Extrusion Plant ABA Two Three Layer Multilayer Mulching Paper Film Plant Garbage Bag Plant Blown Film Plant Liner Film Plant. Film Width from 150650mm.

4555mm or 55mm65mm screw. Film width 300 1500mm. Blown Film Processes and Troubleshootingand Troubleshooting The Ultimate Quality Control Tool Presented by.

T-shirt bags garbage bags flat bag and others. Works with virgin recycled and CaCO3. Blown film lines are used to make shrink wrap films.

Blown Film Properties Purchasing Production Maintenance Raw Material Properties MW MWD Density Processing Conditions Output Melt Temp FLH Equipment Malfunctions Die Size Die Gap Ai Ri. Techno FLEX Blown Film lines for the production of multi-layer film 3. Also cast unwinds quieter and is easier to.

One Layer Twin Head HDPE LDPE 650mm. Blown film towers require large vertical heights. 3 Co-extruders Diameters 507550 LD 303030 Three Layer Coextrusion Head type TBF 16-32 K Cooling ring HK 500 Die diameter 250 mm Internal bubble cooling unit type IBC Nr.

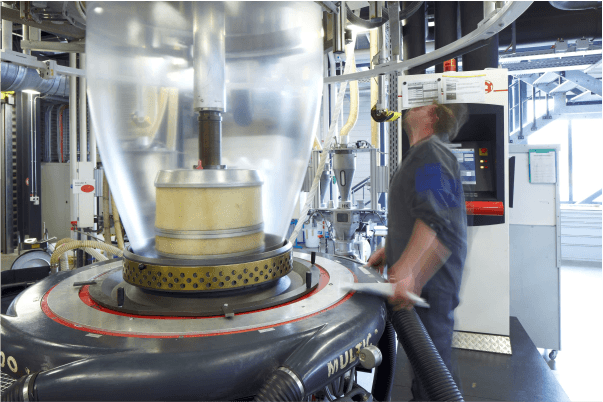

Used Blown film extrusion machines At MachinePoint we have the greatest selection of used Blown film extrusion machines in excellent condition. Can be vary as per requirement Depends upon type of material and type of printing. Feed Section - Grooved Feed.

We can supply machines in different models sizes specification ranging 40 mm to 150 mm screw diameter for 4 inch to 20 ft wide tube. We provide mono layer multi layer aba multicolour machines. 2 45 DDR draw down ratio gap widththickness x BuR MD machine direction TD transverse direction LD ratio of screw.

08 28 mm Bubble diameter BUR blow up ratio. Monolayer Blown Film Machine is a cost effective investment of producing single. 3 Gravimetric Dosing units CONTREX Controll unit for thickness and diameter setting Corona Treatment CASON GHIOLDI Oscillating Take-Off type.

JC-ABA Series - 3 layer Co-Extrusion Blown Film is the ultimate solution producing high quality film at lower production cost. Film width available from 150mm to customized depending on customers requirement suitable for both HDPE The special screw design provides good mixing for both colored with. Capacity is 45 kghour.

Cast machine cast wrap has a glossier clearer finish which allows different scanning technologies to be used. LDPE LLDPE MLLDPE MPE Metallocene HDPE. Blown film lines require lower melt temperatures.

Our machines screw and barrel made of nitrating treatment grinding and hard chrome plating which is durable and give long life to plastic extrusion machinery. Monolayer Blown Film Extrusion Machine With. Blown films provide a better balance of properties between the machine and transverse directions.

The head blows in a downwards direction making this a relatively low machine that easily fits in any hall. 6 250 microns Layflat width. The sheets and film they can produce can be as fine as 10-20 microns 001mm 002mm to 250 microns 025mm thick.

003 to 012 mm 30-120 microns Raw Materials. Check their technical specifications now. This is caused by the slower cooling process that allows the blown film molecules to spread out instead of aligning as they do in cast film.

Most Blown film is either High or Low Density Polyethylene HDPE or. Paul Waller President Plastics Touchpoint Group Inc. Our blown film portfolio offers the right machine for your individual production needs.

Lamination film milk pouches edible oil packaging shrink stretch wrap films surface protection films agricultural films and variety of barrier films our machines make them all. 600 4000mm Die diameter. Blown film can produce up to 130 metres of products in a single minute.

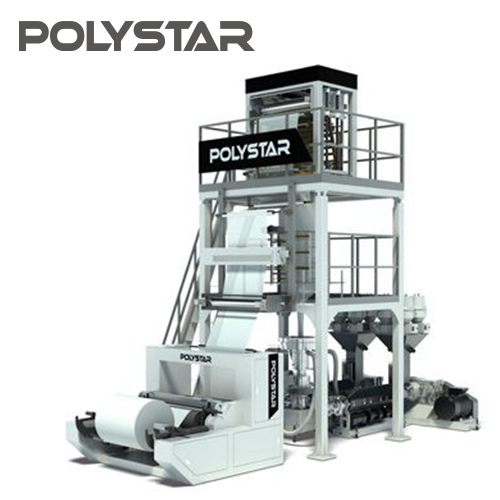

Description Blown FIlm Co-extrusion Line Nr. Compact Type Blown Film Machine The MB mini-type blown film machine is suitable for general packaging prod- ucts such as T-shirt bags supermarket bags flat bags and many others. Twin Head Blown Film Machine.

The outer layer is dominantly with virgin materials and the core layer with large percentage of CaCo3 or in-house recycled. The thickness of the finished film is. Bandera Blown Film extrusion range includes.

Blown film is actually tougher and has less of a chance of puncturing than cast film. Plastic Film Extrusion Machine. SpecificationDeton plastic machines leading exporter and manufacturer of blown film extrusion film blowing machine our machines has produced by using latest technology.

SmartFlex Blown Film lines 1 3 and 5 layers characterized by a competitive investment level maximized flexibility for different applicationsrecipes power consumption reduction functional and compact layout featuring frames modularity. Monolayer Blown Film Machine gives high output up to 280 kghr with thickness ranging from 8 microns to 150 microns and a maximum film width of 2500 mm. This Acmack extrusion line produces PP film.

Suitable Material - Biodegradable compo-stable HM-HDPE LDPE LLDPE. Multilayer Blown Film Machine. Co-Extrusion Three Layer.

We are offering high speed blown film Making Machine. Elements of blown film Film thicness. ABA - HDPE and LDPE.

Our Blown Film Lines are designed to produce high-performance high-quality films for a comprehensive range of applications. The ABA 3 layer co-extrusion line consist two high performance extruders with a 3 layer ABA co-extrusion die head. From pre-optimized solutions for standard products to highly customizable modular solutions to produce demanding products.

The blown film process can produce a wide range of film sizes from the same die. 1000 to 6000 mm. Can be split into smaller widths.

100 600mm Die gap. Carry bags AIr Bubble Sheet Tirpal Shelter film Garbage bags Shopping bags Zip lock bags Other Details.

Process Cooling Blown Film Coolers Berg Chilling Systems

Three Layer Aba Blown Film Machine Polystar Machinery

Plastic Film Extrusion Machine Plastic Blown Film Extrusion Machine Extruder Machine Manufacturers

Wenzhou Aoxiang Packaging Machinery Co Ltd

Three Layer Aba Blown Film Machine Polystar Machinery

Blown Film Machine Blown Film Line Fki Machinery

Pe Blown Film Extrusion Machine Plastic Blow Film Machine Pe Plastic Film Blowing Machine Real Time Quotes Last Sale Prices Okorder Com

Blow Film Machine Film Blowing Machine Polystar Machinery

Three Layer Aba Blown Film Machine Polystar Machinery

Blown Film An Overview Sciencedirect Topics

Mono Layer Film Blowing Machine For Biodegradable Materials Matila Blown Film Extrusion Supply

Process Cooling Blown Film Coolers Berg Chilling Systems

Two Layer Blown Film Machine Polystar Machinery

Hdpe Blown Film Machine Polystar Machinery

Co Extrusion Blown Film Line Internal Bubble Cooling System Ibc

Aba Co Extrusion Blown Film Machine Prm Taiwan B2b Marketplace